Wednesday, August 14, 2013

Safety Isolating Transformer

1. Introduction

The purpose of this module is to set safety standards for safety isolating transformers in technical areas and workshops.

The purpose of this module is to set safety standards for safety isolating transformers in technical areas and workshops.

This guidance does not apply to auto-transformers (which should not be used), transformers used on building sites (110V or 50-0-50V) nor to isolating transformers used in vehicles e.g. OB Scanners and satellite trucks.

The safety isolating transformers covered by this Guidance Note will be various types and will be found:

• as free standing units in workshops

• built in to workshop bench supplies and marked as ‘isolated supply’

• in Radio and TV Studios

• in use with Performers’ equipment in studios

1.1. Safety Isolating Transformers - Principles of operation

A safety isolating transformer is where the input voltage and output voltage are identical, rather than at Separated Extra-Low Voltage (SELV 50V rms maximum), which is strictly the definition in BS 3535. Additionally BS 3535 would exclude the use of domestic socket outlets on the output.

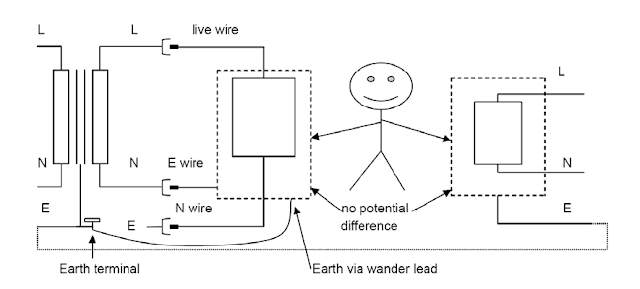

The primary and secondary windings are isolated to Class ll standards by either an earthed electrolytic screen or by being constructed with separate windings on the core. This gives adequate protection from electric shock when working on equipment supplied by such a transformer should either of the supply terminals inside the equipment be touched, as the voltages on the terminals are no longer referred to earth and mains. This is true even if the incoming mains earth is carried through to the equipment chassis.

When such a transformer supplies equipment which normally has a live chassis, a two-wire cable and no internal transformer (e.g. a TV receiver), the hazardous voltage is removed from the chassis as it is floated with respect to mains earth. Touching both terminals at the same time will still result in an electric shock. The problem of using this arrangement during a maintenance operation is that the use of an oscilloscope would not be possible as there would be no earth reference for the probe and the measurement. If the chassis were now grounded by an earth clip to the incoming earth, test equipment such as an oscilloscope could now safely be used and also be correctly referenced.

Commercially produced free-standing/portable safety isolating transformers normally have a BS1363 socket outlet with the earth pin connected to the incoming circuit protective conductor. This does not give maximum protection as will be shown in Appendix 1, and transformers designed/manufactured to BBC Specification were constructed to give an increased degree of protection against a neutral/earth reversal on the equipment. The BBC transformers (UN11/13), which are no longer manufactured, removed the output earth connection from the socket and provided a separate earthed terminal post for connection of an earth lead directly to the chassis of the equipment, to ensure that it was earthed.

As the BBC manufactured unit was no longer available a specification for a suitable unit was written as follows:

A safety isolating transformer is a 240V:240V all-insulated portable Class ll isolating transformer complying with BS3535: Part 1: 1990 or EN 60742:1989 with the following variations:

• the output socket should be an unswitched single socket to BS 1363, with a non conducting casing

• the earth pin of the output socket is to be isolated from the incoming protective conductor to Class ll requirements

• the incoming protective conductor from the supply will be carried through to a green insulated binding post incorporating a 4mm socket to be mounted adjacent to the output socket

The safety isolating transformers covered by this Guidance Note will be various types and will be found:

• as free standing units in workshops

• built in to workshop bench supplies and marked as ‘isolated supply’

• in Radio and TV Studios

• in use with Performers’ equipment in studios

1.1. Safety Isolating Transformers - Principles of operation

A safety isolating transformer is where the input voltage and output voltage are identical, rather than at Separated Extra-Low Voltage (SELV 50V rms maximum), which is strictly the definition in BS 3535. Additionally BS 3535 would exclude the use of domestic socket outlets on the output.

The primary and secondary windings are isolated to Class ll standards by either an earthed electrolytic screen or by being constructed with separate windings on the core. This gives adequate protection from electric shock when working on equipment supplied by such a transformer should either of the supply terminals inside the equipment be touched, as the voltages on the terminals are no longer referred to earth and mains. This is true even if the incoming mains earth is carried through to the equipment chassis.

When such a transformer supplies equipment which normally has a live chassis, a two-wire cable and no internal transformer (e.g. a TV receiver), the hazardous voltage is removed from the chassis as it is floated with respect to mains earth. Touching both terminals at the same time will still result in an electric shock. The problem of using this arrangement during a maintenance operation is that the use of an oscilloscope would not be possible as there would be no earth reference for the probe and the measurement. If the chassis were now grounded by an earth clip to the incoming earth, test equipment such as an oscilloscope could now safely be used and also be correctly referenced.

Commercially produced free-standing/portable safety isolating transformers normally have a BS1363 socket outlet with the earth pin connected to the incoming circuit protective conductor. This does not give maximum protection as will be shown in Appendix 1, and transformers designed/manufactured to BBC Specification were constructed to give an increased degree of protection against a neutral/earth reversal on the equipment. The BBC transformers (UN11/13), which are no longer manufactured, removed the output earth connection from the socket and provided a separate earthed terminal post for connection of an earth lead directly to the chassis of the equipment, to ensure that it was earthed.

As the BBC manufactured unit was no longer available a specification for a suitable unit was written as follows:

A safety isolating transformer is a 240V:240V all-insulated portable Class ll isolating transformer complying with BS3535: Part 1: 1990 or EN 60742:1989 with the following variations:

• the output socket should be an unswitched single socket to BS 1363, with a non conducting casing

• the earth pin of the output socket is to be isolated from the incoming protective conductor to Class ll requirements

• the incoming protective conductor from the supply will be carried through to a green insulated binding post incorporating a 4mm socket to be mounted adjacent to the output socket

2. H&S Legislation

The Electricity at Work Regulations 1989 specifically deal with electrical “systems” in Regulation 4:

(1) All systems shall at all times be of such construction as to prevent, so far as is reasonably practicable, danger.

(2) As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as is reasonably practicable, such danger.

(3) Every work activity, including operation, use and maintenance of a system and work near a system, shall be carried out in such a manner as not to give rise, so far as is reasonably practicable, to danger.

(4) Any equipment provided under these Regulations for the purpose of protecting persons at work on or near electrical equipment shall be suitable for the use for which it is provided, be maintained in a condition suitable for that use, and be properly used.

There is no specific need stated in the Regulations which refers to safety isolating transformers.

3. Hazards and risks

The main hazard associated with electrical equipment is electric shock where a fault condition exists and the first line of protection has also failed, or when working with exposed

mains during maintenance. During maintenance the shock would be by direct contact and there are specific precautions to be taken (as specified in EGN12). The use of safety isolating transformers in specific situations where equipment has a live chassis or where a performer’s own electrical equipment is being used can minimise the risk.

4. Electric Shock Protection

An electric shock is only dangerous when the current is greater than about 10mA. Above this level the risk of electrocution is related to the charge, which is dependent on the duration and size of the current flow. A low current for a long time can be as dangerous as a high current for a short time. The voltage is not important except for causing the current passing through the body. Voltages of over 50V normally cause an involuntary action, which will throw off the body, but in some circumstances the body may become ‘locked on’ to the supply. Currents of over 50mA can cause unconsciousness and if prolonged may lead to death.

The current passing through the body depends on the voltage, contact area, moisture level and the body resistance all of which can vary considerably. Under dry conditions the body resistance may be 1500 ohms but can fall to 200 ohms; with a 230V mains supply, this would give currents of about 150mA and 1.2 amps respectively. Such currents could easily cause electrocution, as a normal fuse or circuit breaker would not be expected to break and disconnect the supply. Methods of protection include the use of an RCD or a safety isolating transformer.

5. Selection, use and maintenance of Safety Isolating Transformers

So far as they relate to matters within their control and as is necessary to prevent injury arising, managers must ensure that :

5.1. Selection of safety isolating transformers

5.1.1. Safety isolating transformers are chosen according to their intended conditions and purpose of use

5.1.1.1. Guidance on choice of transformer.

Any transformer should have adequate power rating for the equipment it is to supply. A unit capable of 13 amps (3kW) is probably best, subject to inrush current problems, but the physical size may be a limiting factor in the choice. The BBC transformer unit is rated at 250W (1.1amps) continuous duty, the BBH GU500 at 500W (2.2amps) continuous. If the unit is installed as a bench socket it must be clearly labelled with its maximum load capability.

5.1.1.2. Portable safety Isolating Transformers

Some BBC manufactured units may still be available and should be used subject to passing the Class ll tests. There will be other units from BBH, Farnell or RS that have been suitably modified (Radio Engineering Report R89/68 and R90/2) and they may be also be used subject to satisfactory testing.

5.1.1.3. Installed safety isolating transformers

Installed transformers may be provided on benches in workshops.

These must meet the Class ll requirement. A suitable transformer by RS Components is the TIM300 RS part 278-7103 with the secondary windings in series to give 230V at 1.3A.

5.1.2. A bench-top isolated supply is separated from other outlets providing normal mains, is clearly labelled and has a separate labelled earth terminal

5.1.2.1. Guidance for labelling socket outlets

The label should read :‘Isolated output, earth-free’ ‘earth socket not connected’ ’maximum load……’

5.2. Use of safety isolating transformers

The following requirements define the use of safety isolating transformers:

• a suitable safety isolating transformer is used whenever the risk assessment identifies the need

• a visual inspection is carried out of all safety isolating transformers before use to check there are no obvious signs of damage

• a separate safety isolating transformer is used for each item of equipment

5.2.1.1. Guidance on the use of a safety isolating transformer

A safety isolating transformer protects against contact with one mains terminal but will not protect against contact with both terminals. If the safety Isolating transformer is in floating mode (not reference to ground), then, as soon as one terminal on the secondary side is touched the other terminal is no longer floating and becomes live and a hazard. For this reason, the chassis of the unit under test should be directly connected to the earth terminal of the transformer i.e. the incoming mains earth, as this is the part most likely to be touched, this ensures that it is at a safe potential.

If the equipment has a live chassis, and depending upon circumstances, you should work using a safety isolating transformer in either of the two following ways:

a) equipment under test remains floating - this is satisfactory provided that only alignment (e.g. potentiometers being adjusted) or voltage measurement (with a digital voltmeter) is being carried out. If you need to take measurements where the measuring device is referred to earth, such as an oscilloscope, then the results will not be satisfactory and an alternative method should be used. If you have to remain in floating mode then the oscilloscope needs to floated on a separate safety isolating transformer.

b) chassis of the equipment under test is connected to mains earth, usually from an earth terminal on the safety isolating transformer (on a BBC Type UN11/13 safety isolating transformer where available) or one provided for the purpose. The chassis is then safe to touch but all other voltages are referred to earth and may be hazardous.

5.2.1.2. Safety isolating transformer or residual current device?

An RCD can be used with high current equipment and more than one piece of equipment can be fed from any one RCD. As soon as a safety isolating transformer is used however, the

protection from an RCD ceases to the secondary windings of the transformer, the cables and equipment connected to the secondary windings.

High current equipment can be accommodated without the bulk and weight of a suitable high power safety isolating transformer.

In most cases the RCD offers greater protection than a safety isolating transformer. This may only be determined by a risk assessment. However neither an RCD nor an isolating transformer should be relied upon to make it safe to work with equipment, other precautions should be taken - see EGN 10 and EGN 3 for more information.

5.3. Maintenance of safety isolating transformers

All safety isolating transformers are suitably maintained, and where appropriate, tested by a competent person.

5.3.1.1. Guidance for maintenance of safety isolating transformers.

The maintenance regime for safety isolating transformers require :

• visual inspection - to check plug for damage, the fuse within the plug and transformer is correctly rated, for damage to the mains lead and damage to insulated cases.

• class II insulation test - between input and output L and N terminals. Additionally carry out the test between input earth and the earth pin of the output socket on a BBC type transformer.

• earth continuity test - between the input earth connector and the output earth connector, including any earth binding post.

Up to date records should be kept which demonstrate the maintenance carried out to ensure that the safety isolating transformers are being maintained in a safe condition.

All safety isolating transformers are suitably maintained, and where appropriate, tested by a competent person.

5.3.1.1. Guidance for maintenance of safety isolating transformers.

The maintenance regime for safety isolating transformers require :

• visual inspection - to check plug for damage, the fuse within the plug and transformer is correctly rated, for damage to the mains lead and damage to insulated cases.

• class II insulation test - between input and output L and N terminals. Additionally carry out the test between input earth and the earth pin of the output socket on a BBC type transformer.

• earth continuity test - between the input earth connector and the output earth connector, including any earth binding post.

Up to date records should be kept which demonstrate the maintenance carried out to ensure that the safety isolating transformers are being maintained in a safe condition.

6. Special cases- Performing Band electrical and musical equipment

When bands bring electrical equipment into studios the normal practice has been to supply their equipment from a safety isolating transformer to prevent electrical shock from unknown hazards. More recently it has been the practice to supply from an RCD. However it is known that bands often remove the earth from the mains plug to prevent ‘hum loops’. This is a dangerous practice and if there are hum loops present it is the signal cable earth/screen which should be disconnected at one end only. HSE GS50 gives guidance on this and states that the ‘removal of the protective earth connection is the most common cause of entertainers receiving shocks, some of which have been fatal’. See EGN3.

If a separate safety isolating transformer is used to supply each item of equipment then it may not be necessary to carry out a PAT test as each item is protected by isolation and this method of working may then give the best protection. This will almost certainly mean that a fairly large number of transformers will be required.

The use of a safety isolating transformer remains the recommended practice, as an isolating transformer will prevent the shock whereas an RCD will only reduce the severity of any shock.

7. Appendix

Reasons for additional protection given by use of the suggested type transformer

Off the shelf safety isolating transformer.

Reasons for additional protection given by use of the suggested type transformer

Off the shelf safety isolating transformer.

Equipment has earth-neutral reversal. It will work direct from mains but there is, of course, a hazard. When connected via a standard safety isolating transformer it does not function, and the case rises to 230V with respect to earth.

Improved safety with new method.

Improved safety with new method.

If the earth-neutral exists in the plug of the equipment being supplied, the equipment will not work. There are now no dangerous voltages exposed.

However it is probably safer to leave the equipment with no connection from chassis to earth. Better still once it is obvious that the equipment will not work the fault should be investigated

Labels:

isolating,

safety,

transformer